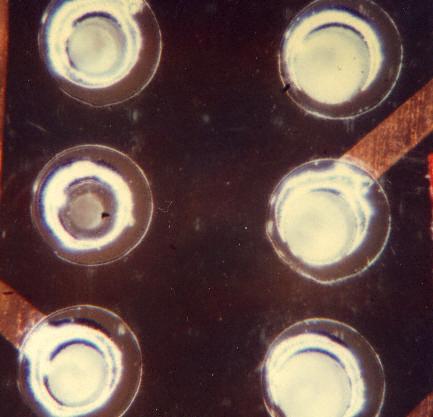

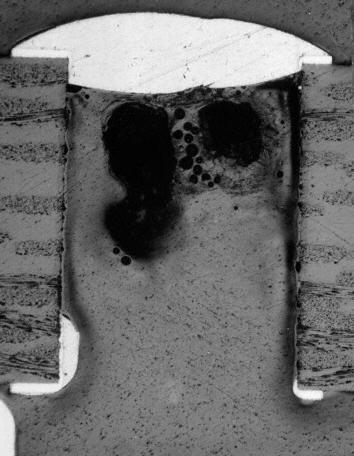

Solder filled through-hole

Description:

Solder filled through-hole. There is too much solder at the walls of the through-hole. The successive placing of components could be considerably impaired. For a through-hole as such there is not enough solder. Partially acceptable defect.

Causes/Remedy:

- deficiencies in the soldering process (soldering angle, temperature)

- deficiencies in hot tinning for THD

Source:

Source:Microsection

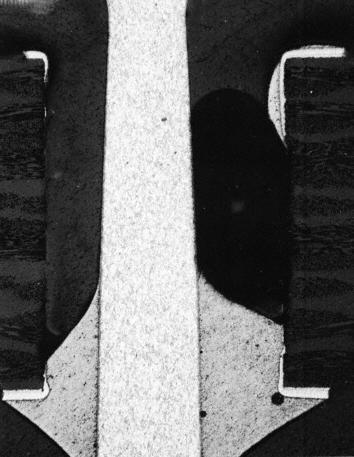

Description:

same context as described above - general view

Causes/Remedy:

- deficiencies in the soldering process (soldering angle, temperature)

Source:

Source:visual, optical inspection - general view

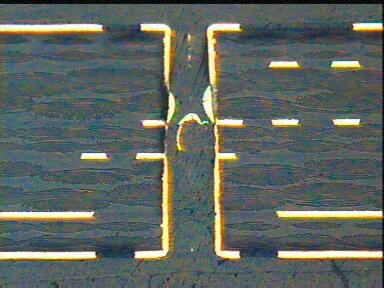

Missing metallization

Description:

Thin metallization missing in a multilayer THD. Not acceptable

Causes/Remedy:

- deficiencies in the galvanizing process (copper)

Source:

Source:visual, optical inspection - general view

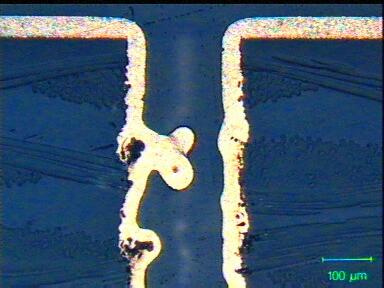

Formation of burrs

Description:

Formation of burrs in the wake of drilling the boards. These residues of drilling which have not been removed (particles of base material, burr) were plated with copper in the successive electro-plating process and therefore block the passage. Not acceptable.

Causes/Remedy:

- insufficient cleaning after drilling

- drilling process not optimal

Source:

Source:Microsection

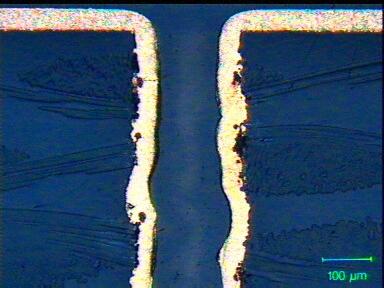

Description:

Same context as above, but to lesser extent.

Causes/Remedy:

- insufficient cleaning after drilling

- drilling process not optimal

Source:

Source:Microsection

Missing copper coating

Description:

Missing copper coating in a THD. Result: There is no surface to be wetted with solder. Not acceptable.

Causes/Remedy:

- deficiencies in galvanizing process (copper)

Source:

Source:Microsection

Description:

Because of missing copper coating this THD solder joint could not be done properly. Not acceptable.

Causes/Remedy:

- deficiencies in galvanizing process (copper)

- hole reveals very uneven walls (unsatisfactory)

Source:

Source:Microsection

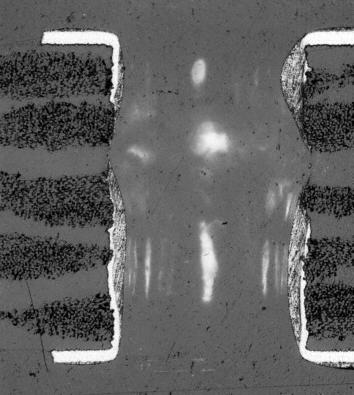

Partly missing copper coating

Description:

Due to partly missing copper coating in the through hole the solder could not fully wet required area. Not acceptable.

Causes/Remedy:

- deficiencies in galvanizing process (copper)

- hole reveals very uneven walls (unsatisfactory)

Source:

Source:Microsection

Our analytics team can help you find the cause.

go to failure analysis at TechnoLab