Attention ! Reference is always made to the current standards. They are often not comparable. Here DIN EN 61191, Part 1 - 4, and IEC 61191, Part 1 - 4 respectively are taken as reference basis. The assessment of all solder joints is based on the standards given above.

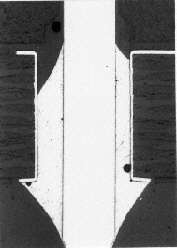

Incomplete solder fillet

Description:

Incomplete solder fillet at a pin of a THD. According to IEC 61191-3 this is still acceptable, since the solder fillet reaches 75 % of the through-hole. Nevertheless the cause for this deficiency should be looked for and made sure that it is no systematic fault.

Causes/Remedy:

- poor wettability of component

- poor wettability of through-hole

- unsuitable soldering process parameter

- contamination of materials to be joined

Source:

Source:Microsection

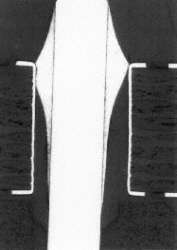

Missing solder fillet

Description:

Completely missing solder fillet. This fault is unacceptable and has to be reworked in any case. Since this fault only becomes clearly visible in a micrograph, optical inspection has to pay special attention to similar appearances.

Causes/Remedy:

- poor wettability of component

- poor wettability of through-hole

- unsuitable soldering process parameter

- contamination of materials to be joined

Source:

Source:Microsection

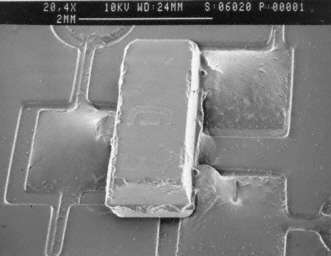

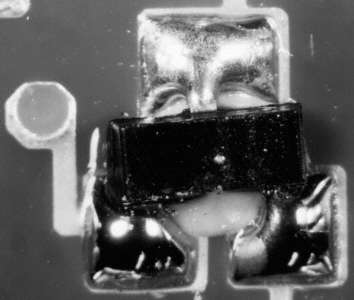

Defective solder fillet

Description:

Defective solder fillet at a CMC after wave soldering caused by excessive adhesive being pushed onto the landing pad after placing. This defect can hardly be assessed from outside, since the condition under the component cannot be seen. According to the standard the width of the solder fillet is sufficient, but rework should nevertheless be carried out.

Causes/Remedy:

- poor adhesive application (excessive quantity, positioning)

- deficiencies in placing (excessive force)

Source:

Source:SEM

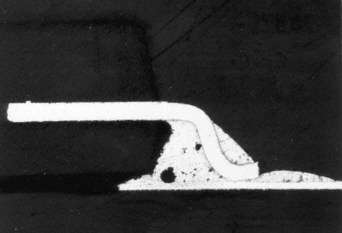

Wetability problems

Description:

Example of the varying wettability of SOT23 leads. The photos show immaculate solder joints. All contact areas have been well wetted with the exception of the front end of the lower lead. This fact shows however that wettability problems can arise at the cutting edges of the lead-frames. They are particularly frequent with components which have been stored for a long time or with components with alloy 42 lead-frames. This phenomenon can decisively influence the solder fillet. The photo below shows a micrograph of this example.

Causes/Remedy:

- poor wettability of the cutting edges of the lead-frames

- alloy 42 can result in poor wettability

Source:

Source:SEM

Source:

Source:Microsection

Description:

Defective solder fillet after wave soldering of a SOT23. This defect was caused by excessive adhesive which was pushed onto the landing pad after placing. It can hardly be assessed from outside, since the condition under the component cannot be seen. In this case the solder fillets at the heel of the component leads could not be wetted correctly. This defect is nonconforming.

Causes/Remedy:

- poor adhesive application (excessive quantity, positioning)

- deficiencies in placing (excessive force)

Source:

Source:visual, optical inspection - general view

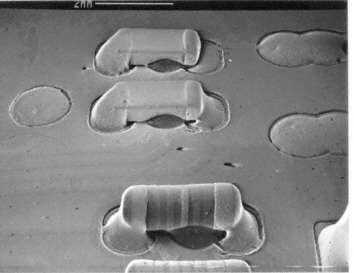

Adhesive particles on the landing pads

Description:

Adhesive particles on the landing pads prevent standard solder joints. The component at the very top of the photo (CMC) has even not been soldered. For the components in the middle and at the bottom (CMC, MiniMELF) the length of the solder joint (under the component) was decisively shortened. Neither of these is acceptable.

Causes/Remedy:

- poor adhesive application (excessive quantity, positioning)

- deficiencies in placing (excessive force)

Source:

Source:SEM

Our analytics team can help you find the cause.

go to failure analysis at TechnoLab