Examples: SMD-adhesive, varnish for marking print on board, resist coating. Contact areas constantly at risk.

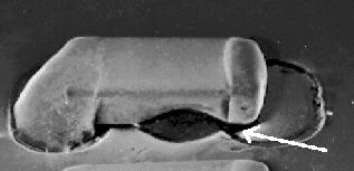

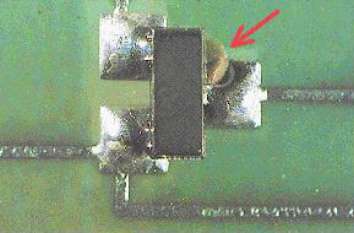

Residues at CMC

Description:

Open (right) at a CMC due to deposition of excessive adhesive before wave soldering. The placing of the component made the adhesive come out from under it and reach over the pad. As a consequence the component was not soldered. Rework is necessary in any case.

Causes/Remedy:

- unsuitable machine parameter for deposition of adhesive

- adhesive (viscosity) unsuited

- poor positioning of adhesive

Source:

Source:SEM

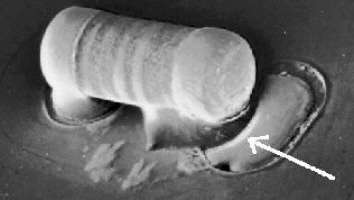

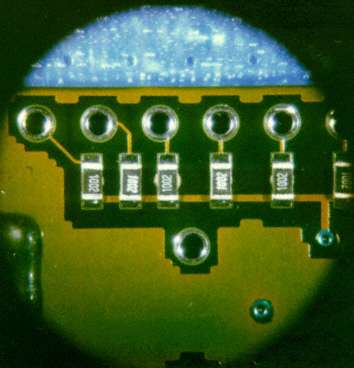

Residues at MiniMELF

Description:

see CMC example; same context as above, however at a MiniMELF resistor.

Causes/Remedy:

- unsuitable machine parameter for deposition of adhesive

- adhesive (viscosity) unsuited

- poor positioning of adhesive

Source:

Source:SEM

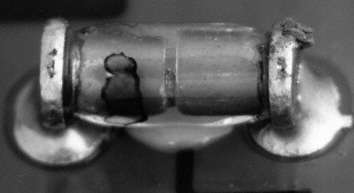

Residues at SOD

Description:

Unidentified residues on the contact metallisation of a SOD after wave soldering. This contamination which occurred during soldering prevented the solder from wetting the complete metallisation area of the component. It could not be established what caused it. Apart from this contamination the solder (alloy) had been polluted beforehand.

Causes/Remedy:

- polluted solder

- pollution of the solder alloy

- contamination of the solder or the board (flux residues or similar)

- Particles of substances from other components (e.g. plastics)

Source:

Source:visual, optical inspection - general view

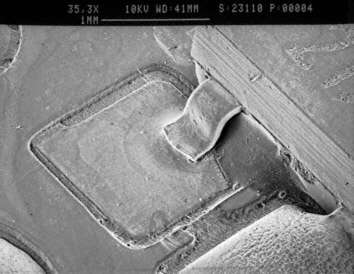

Rückstände bei SOT23

Description:

Non-soldered lead of a SOT23. The spilling-out of adhesive impaired the wetting during the wave soldering process. The adhesive is on the pad under the lead . Rework is necessary. The component should be removed completely and the contact areas of the lead cleaned from adhesive residue.

Causes/Remedy:

- unsuitable machine parameter for deposition of adhesive

- adhesive (viscosity) unsuited

- poor positioning of adhesive

Source:

Source:SEM

Description:

Same context as described above. The adhesive spilled out from under the component body is clearly visible.

Causes/Remedy:

- unsuitable machine parameter for deposition of adhesive

- adhesive (viscosity) unsuited

- poor positioning of adhesive

Source:

Source:visual, optical inspection - general view

Residues, general

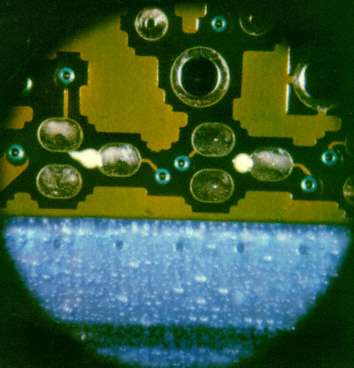

Description:

Clearly visible spilling-out of excessive adhesive from under a square-shaped resistor (center), which, however, did not prevent soldering in this case.It is remarkable that only one component shows this defect. This fact indicates that the process parameter (process stability) have not been monitored closely enough.

Causes/Remedy:

- unsuitable machine parameter for deposition of adhesive

- adhesive (viscosity) unsuited

- process parameter (temperature)

Source:

Source:visual, optical inspection - general view

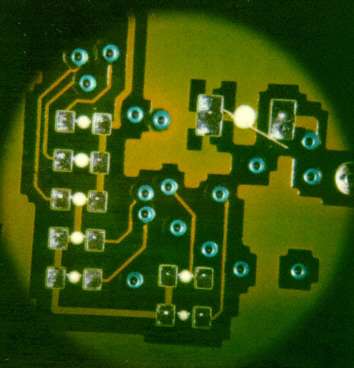

Poor dispensing of adhesive

Description:

In this case poor dispensing of adhesive before placing the components led to the following defects:

- depots of different sizes

- movement of dispensing machine caused strings of adhesive

Causes/Remedy:

- poor machine paramenter for dispensing of adhesive

- unsuitable adhesive (viscosity)

- process conditions (temperature)

- poor teaching of machine (sequence of motions)

Source:

Source:visual, optical inspection - general view

Description:

Classical fault during dispensing of adhesive before placing components. The example clearly shows the string of adhesive which sticks out from the main depot and even reaches the pad. This would lead to opens.

Causes/Remedy:

- poor machine paramenter for dispensing of adhesive

- unsuitable adhesive (viscosity)

- process conditions (temperature)

- poor teaching of machine (sequence of motions)

Source:

Source:visual, optical inspection - general view

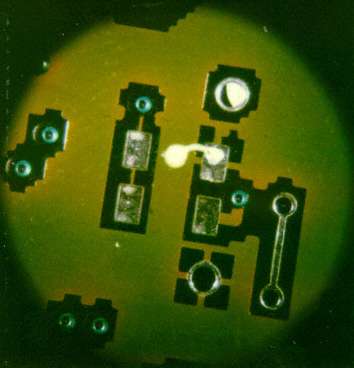

Description:

Misplaced depots of adhesive. Since the dispensing machine did not move accurately, the area where adhesive can be deposited were left. Adhesive is clearly visible on the pads.

Causes/Remedy:

- poor machine paramenter for dispensing of adhesive

- unsuitable adhesive (viscosity)

- process conditions (temperature)

- poor teaching of machine (sequence of motions)

Source:

Source:visual, optical inspection - general view

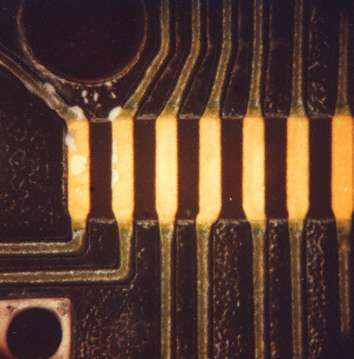

Contamination

Description:

This example shows contamination on the uncovered, wettable studs of conductors. Since this defect was detected on bare-boards, the contamination must be due to particles / substances from the galvanic processes. Contamination through inexpert storing or transport cannot be ruled out either. This contamination can lead to defects during soldering (opens due to non-wetting).

Causes/Remedy:

- manufacturing fault during galvanizing process

- contamination as a consequence of inexpert storage/transport (cover foil)

- cleaning necessary

- contamination during preceding production processes

Source:

Source:visual, optical inspection - general view

Our analytics team can help you find the cause.

go to failure analysis at TechnoLab