As a flux-involving soldering process necessarily also means that some solving agent residues are contained in flux and solder paste, the formation of gases is unavoidable; the design of the solder joints and/or the possibility for the gases to evaporate are essential factors for avoiding or reducing them.

Cavities, pores, general

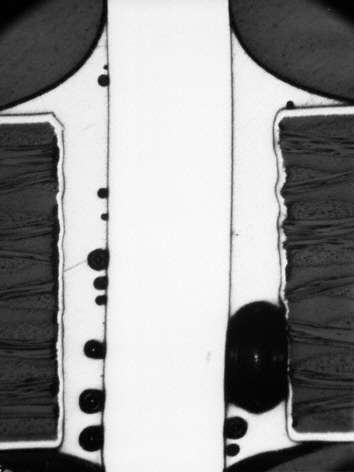

Description:

In this example the pores or cavities in solder joints are due to outgassing from the organic base material. But contamination of the leads / pins also favours this effect. There are no general assessment principles for quantity and size of cavities. But pores which are neighbouring each other like links of a chain increase the susceptibility for cracks of solder joints and therefore impair their mechanical robustness. The same applies to very large cavities. As these pores and cavities are not visible from outside, an inspection is not possible (except X-ray). This solder joint should undergo rework.

Causes/Remedy:

- humidity in the base material

- organic contamination on the base material and the components

- best-before date of components exceeded

Source:

Source:Microsection

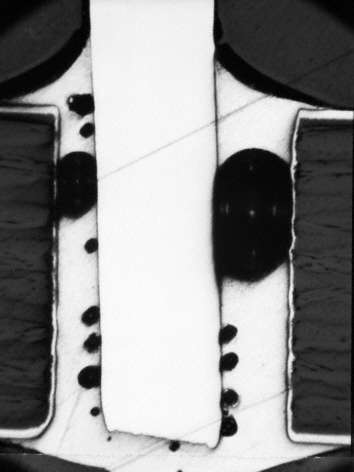

Description:

Same context as described above. This solder joint is not acceptable.

Causes/Remedy:

- humidity in the base material

- organic contamination on the base material and the components

- best-before date of components exceeded

Source:

Source:Microsection

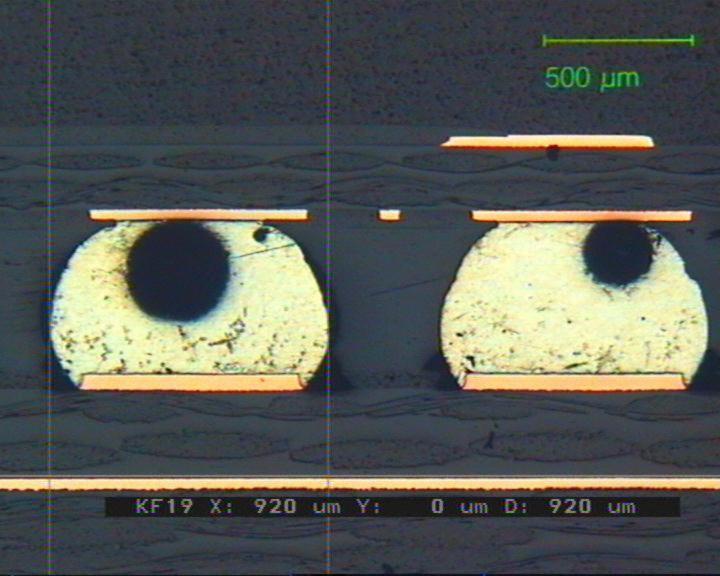

Cavities, pores at BGAs

Description:

This phenomenon can also be observed with the technologically latest components (BGA). Assessment is made on the same principles as described above. For these components however, it is more likely that the defects are detected, because X-ray inspection systems are quite often used for the solder joints which are not visible from outside. The size of the pores in this case is not acceptable.

Causes/Remedy:

- humidity in the base material

- organic contamination on the base material and the components

- best-before date of components exceeded

- poor or unsuitable solder paste

- time lap between solder paste application and soldering too long (solder paste is hygroscopic)

Source:

Source:Microsection

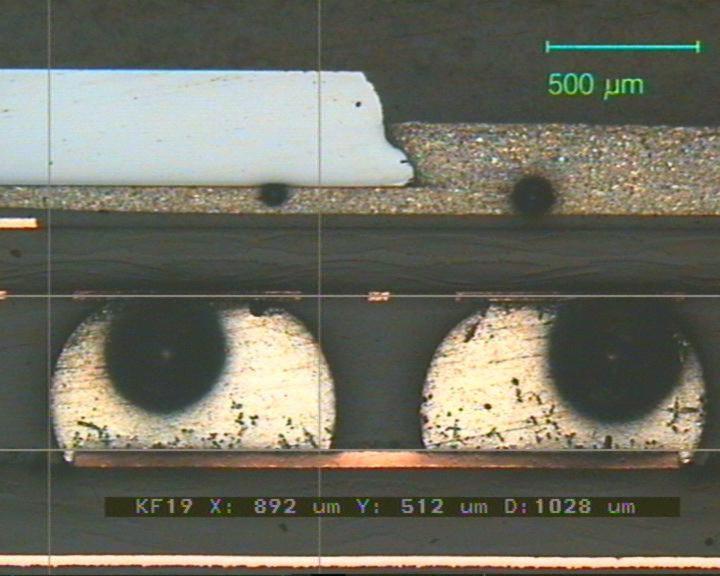

Description:

Same as above. Pore account for more than 50% of the height of the solder joint. Nonconforming solder joint.

Causes/Remedy:

- humidity in the base material

- organic contamination on the base material and the components

- best-before date of components exceeded

- poor or unsuitable solder paste

- time lap between solder paste application and soldering too long (solder paste is hygroscopic)

Source:

Source:Microsection

Our analytics team can help you find the cause

go to failure analysis at TechnoLab